TS-7250-V3 Hardware Manual Test 2

| WARNING: | This is not the current latest manual for the TS-7250-V3, this is a page for testing new manual layouts. Please return to the TS-7250-V3 manual for the latest up to date manual! |

| |

| Product Page | |

| Documentation | |

|---|---|

| Schematic | |

| FTP Path | |

| Processor | |

| NXP i.MX6UL | |

| 696 MHz Arm® Cortex®-A7 | |

| i.MX6UL Product Page | |

| CPU Documentation |

Overview

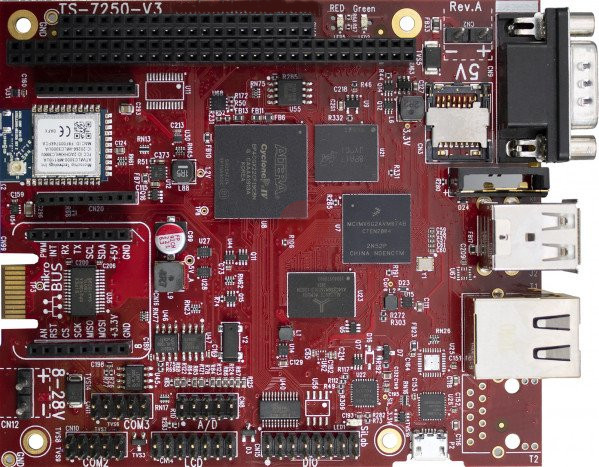

The TS-7250-V3 is a PC/104 form factor SBC with a PC/104 bus, mikroBUS socket, Digi XBee header, soldered down eMMC flash, dual Ethernet, microSD socket, and a Wi-Fi/Bluetooth LE module. This platform also provides a migration path from the TS-7250-V2 and TS-7250 series systems.

Feature Comparison

This platform has multiple hardware variants, please see the TS-7250-V3 product configurations for a comparison of the feature sets by model.

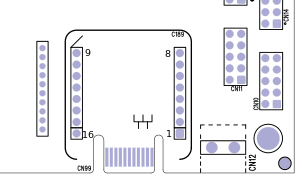

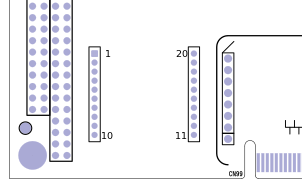

Physical description / connectors / something

IMAGE OF PLATFORM HERE WITH CONNECTORS ANNOTATED IN SOME WAY

Table of different components/features/connectors linked to sections below?

I like the idea of maybe different sections within the table Something like

System I/O

| Feature | Description | Location |

|---|---|---|

| ADC | ADC input | A/D Header / CN8 |

Node Description Location? Jumpers and LEDs jp block | What its for | CNwhatever LED1,2,3 | What they do | CNwhtever Power in | Power input | ... Batt | battery for RTC | ... ? Storage emmc | soldered down | eMMC? sd | SD socket | CNwhatever System IO eth | eth | Twhatever cpu? | cpu | What? USB | usb | CNwhatever CAN | Can interface | COM3 / CN11 ? etc.

Features

ADC

This platform has 5 channels of 12-bit ADC via the i.MX6UL CPU. All channels can sample 0-30 VDC, with channels 1-3 selectively able to sample 0-20 mA current loop input. To minimize noise, the ADC pins use a dedicated analog ground available on the even pins of the header. See the ADC Header section for more details.

The current loop measurement can be dynamically enabled by setting the relevant GPIO pin to a logical 1.

| ADC Header Pin | Schematic Name | ADC Base Register Address | ADC Channel | Voltage Range | Current Range | Current Loop Enable GPIO Bank Address | Current Loop Enable GPIO Pin |

|---|---|---|---|---|---|---|---|

| 1 | AN_CH1 | 0x02198000 | 0 | 0-30 VDC | 0-20 mA | 0x020AC000 | 7 |

| 3 | AN_CH2 | 0x02198000 | 1 | 0-30 VDC | 0-20 mA | 0x020AC000 | 8 |

| 5 | AN_CH3 | 0x02198000 | 5 | 0-30 VDC | 0-20 mA | 0x020AC000 | 9 |

| 7 | AN_CH4 | 0x02198000 | 8 | 0-30 VDC | N/A | N/A | N/A |

| 8 | AN_CH5 | 0x02198000 | 9 | 0-30 VDC | N/A | N/A |

Bluetooth

The TS-7250-V3 supports Bluetooth 5.0 LE via the WILC3000 Wi-Fi / Bluetooth module.

Both Wi-Fi and Bluetooth can be active at the same time on this platform. Note however, that either the Wi-Fi interface needs to be not brought up if Wi-Fi is unused, or it needs to actively connect to an access point or act as an access point.

See the software manual for the software image in use (boy that needs to be worded better) for more information on bringing up and testing the interface.

Once enabled and firmware loaded, the Bluetooth interface is available on the UART device /dev/ttymxc2 at 115200 baud with no flow control.

CAN

The i.MX6UL CPU has two FlexCAN ports which are available on the COM3 Header / CN11.

Both ports conform to CAN 2.0B and ISO 11898 specifications, allowing for communication at speeds up to 1 Mbaud with high noise immunity.

CAN interfaces on the TS-7250-V3 do not provide built-in bus termination resistors. This allows the interfaces to be placed anywhere along the CAN bus. Termination resistors should be added at the ends of the CAN bus where required.

In software, the hardware CAN1 interface will resolve as the first port. For example, in Linux this is the network interface can0. The hardware CAN2 interface resolves as the second interface.

See the corresponding software manual for information on interfacing with the CAN hardware (this needs to be reworded and linked better).

CPU

This device uses the i.MX6UL CPU, running at up to 696 MHz, based upon a Cortex-A7 core and targeting low power consumption.

Refer to NXP's documentation for more detailed information on the i.MX6UL.

GPIO

The i.MX6UL CPU and FPGA GPIO are exposed using the gpiod interface.

See the software manual for the software image in use (boy that needs to be worded better) for more information on interfacing with GPIO pins.

CPU GPIO

| Schematic Net Name | GPIO Bank Base Register | GPIO Pin | Location |

|---|---|---|---|

| AN_CH1 | 0x0209C000 | 0 | ADC Pin 1 |

| AN_CH2 | 0x0209C000 | 1 | ADC Pin 3 |

| EN_SD_CARD_3.3V [1] | 0x0209C000 | 4 | Onboard |

| AN_CH3 | 0x0209C000 | 5 | ADC Pin 5 |

| AN_CH4 | 0x0209C000 | 8 | ADC Pin 7 |

| AN_CH5 | 0x0209C000 | 9 | ADC Pin 9 |

| SEL_XBEE_USB [2] | 0x0209C000 | 11 | Onboard USB MUX |

| FPGA_RESET [3] | 0x0209C000 | 13 | Onboard |

| EN_RED_LED# [4] | 0x0209C000 | 18 | Onboard LED5 |

| EN_GRN_LED# [4] | 0x0209C000 | 19 | Onboard LED2 |

| EN_XBEE_USB [1] | 0x0209C000 | 21 | Onboard |

| UART4_TXD | 0x0209C000 | 28 | Modem UART |

| UART4_RXD | 0x0209C000 | 29 | Modem UART |

| EN_DIO_FET | 0x0209C000 | 30 | DIO Header pin 4 |

| NIM_PWR_ON | 0x0209C000 | 31 | Onboard |

| EN_USB_5V [5] | 0x020A4000 | 0 | Onboard |

| ISA_RESET | 0x020A4000 | 7 | PC104 B2 |

| ISA_IOCHK | 0x020A4000 | 8 | PC104 A1 |

| LCD_PIN7 | 0x020A4000 | 9 | LCD Header pin 7 |

| LCD_PIN8 | 0x020A4000 | 10 | LCD Header pin 8 |

| LCD_PIN9 | 0x020A4000 | 11 | LCD Header pin 9 |

| LCD_PIN10 | 0x020A4000 | 12 | LCD Header pin 10 |

| LCD_PIN11 | 0x020A4000 | 15 | LCD Header pin 11 |

| LCD_PIN12 | 0x020A4000 | 16 | LCD Header pin 12 |

| LCD_PIN13 | 0x020A4000 | 17 | LCD Header pin 13 |

| LCD_PIN14 | 0x020A4000 | 18 | LCD Header pin 14 |

| LCD_WR# | 0x020A4000 | 19 | LCD Header pin 6 |

| LCD_EN | 0x020A4000 | 20 | LCD Header pin 5 |

| LCD_RS | 0x020A4000 | 21 | LCD Header pin 3 |

| SYS_RESET# [6] | 0x020A4000 | 22 | Onboard |

| FPGA_FLASH_SELECT [1] | 0x020A8000 | 0 | Onboard |

| DETECT_94-120 [1] | 0x020A8000 | 1 | Onboard |

| EN_EMMC_3.3V [1] | 0x020AC000 | 2 | Onboard eMMC |

| WIFI_RESET# | 0x020AC000 | 5 | Onboard WIFI |

| EN_WIFI_PWR | 0x020AC000 | 6 | Onboard WIFI |

| EN_CL_1 | 0x020AC000 | 7 | ADC Current loop enable |

| EN_CL_2 | 0x020AC000 | 8 | ADC Current loop enable |

| EN_CL_3 | 0x020AC000 | 9 | ADC Current loop enable |

FPGA GPIO

| Schematic Net Name | GPIO Bank Base Register | GPIO Pin | Location |

|---|---|---|---|

| DIO_PIN1 | 0x50004010 | 1 | DIO Header pin 1 |

| DIO_PIN3 | 0x50004010 | 2 | DIO Header pin 3 |

| DIO_PIN5 | 0x50004010 | 3 | DIO Header pin 5 |

| DIO_PIN7 | 0x50004010 | 4 | DIO Header pin 7 |

| DIO_PIN8 | 0x50004010 | 5 | DIO Header pin 8 |

| DIO_PIN9 | 0x50004010 | 6 | DIO Header pin 9 |

| DIO_PIN11 | 0x50004010 | 7 | DIO Header pin 11 |

| DIO_PIN13 | 0x50004010 | 8 | DIO Header pin 13 |

| DIO_PIN15 | 0x50004010 | 9 | DIO Header pin 15 |

| DIO_SPI_MISO [7] | 0x50004010 | 10 | SPI MISO |

| DIO_SPI_CS# [8] | 0x50004010 | 11 | DIO Header pin 6 |

| DIO_SPI_CLK [8] | 0x50004010 | 14 | DIO Header pin 14 |

| DIO_SPI_MOSI [8] | 0x50004010 | 15 | DIO Header pin 12 |

| ISA_AEN [9] | 0x50004040 | 0 | PC104 Header pin A11 |

| ISA_BALE | 0x50004040 | 1 | PC104 Header pin B28 |

| ISA_TC | 0x50004040 | 2 | PC104 Header pin B27 |

| ISA_ENDX | 0x50004040 | 3 | PC104 Header pin B08 |

| EN_NIMBEL_3V3 | 0x50004040 | 4 | Skywire VIN voltage |

| ISA_IORDY | 0x50004040 | 5 | PC104 Header pin A10 |

| ISA_REFRESH | 0x50004040 | 6 | PC104 Header pin B19 |

| ISA_DRQ1 | 0x50004040 | 7 | PC104 Header pin B18 |

| ISA_DACK1 | 0x50004040 | 8 | PC104 Header pin B17 |

| ISA_DRQ2 | 0x50004040 | 9 | PC104 Header pin B06 |

| ISA_DACK2 | 0x50004040 | 10 | PC104 Header pin B26 |

| EN_NIMBEL_4V | 0x50004040 | 11 | Skywire VIN voltage |

| ISA_DRQ3 | 0x50004040 | 12 | PC104 Header pin B16 |

| ISA_DACK3 | 0x50004040 | 13 | PC104 Header pin B15 |

| MIKRO_RESET# | 0x50004054 | 0 | mikroBUS Header pin 2 |

| MIKRO_AN | 0x50004054 | 1 | mikroBUS Header pin 1 |

| MIKRO_INT | 0x50004054 | 2 | mikroBUS Header pin 15 |

| MIKRO_180 [10] | 0x50004054 | 3 | Onboard |

| MIKRO_PWM [11] | 0x50004054 | 4 | mikroBUS Header pin 16 |

| MIKRO_SPI_CS# [12] | 0x50004054 | 5 | mikroBUS Header pin 3 |

| MIKRO_SPI_CLK [12] | 0x50004054 | 6 | mikroBUS Header pin 4 |

| MIKRO_SPI_MISO [12] | 0x50004054 | 7 | mikroBUS Header pin 5 |

| MIKRO_SPI_MOSI [12] | 0x50004054 | 8 | mikroBUS Header pin 6 |

| MIKRO_TXD [13] | 0x50004054 | 9 | mikroBUS Header pin 13 |

| MIKRO_RXD [13] | 0x50004054 | 10 | mikroBUS Header pin 14 |

| MIKRO_I2C_DAT [14] | 0x50004054 | 11 | mikroBUS Header pin 11 |

| MIKRO_I2C_CLK [14] | 0x50004054 | 12 | mikroBUS Header pin 12 |

| ISA_DAT00 [9] | 0x5000405C | 0 | PC104 Header pin A9 |

| ISA_DAT01 [9] | 0x5000405C | 1 | PC104 Header pin A8 |

| ISA_DAT02 [9] | 0x5000405C | 2 | PC104 Header pin A7 |

| ISA_DAT03 [9] | 0x5000405C | 3 | PC104 Header pin A6 |

| ISA_DAT04 [9] | 0x5000405C | 4 | PC104 Header pin A5 |

| ISA_DAT05 [9] | 0x5000405C | 5 | PC104 Header pin A4 |

| ISA_DAT06 [9] | 0x5000405C | 6 | PC104 Header pin A3 |

| ISA_DAT07 [9] | 0x5000405C | 7 | PC104 Header pin A2 |

| ISA_DAT08 [9] | 0x5000405C | 8 | PC104 Header pin C11 |

| ISA_DAT09 [9] | 0x5000405C | 9 | PC104 Header pin C12 |

| ISA_DAT10 [9] | 0x5000405C | 10 | PC104 Header pin C13 |

| ISA_DAT11 [9] | 0x5000405C | 11 | PC104 Header pin C14 |

| ISA_DAT12 [9] | 0x5000405C | 12 | PC104 Header pin C15 |

| ISA_DAT13 [9] | 0x5000405C | 13 | PC104 Header pin C16 |

| ISA_DAT14 [9] | 0x5000405C | 14 | PC104 Header pin C17 |

| ISA_DAT15 [9] | 0x5000405C | 15 | PC104 Header pin C18 |

| ISA_ADD_00 [9] | 0x50004064 | 0 | PC104 Header pin A31 |

| ISA_ADD_01 [9] | 0x50004064 | 1 | PC104 Header pin A30 |

| ISA_ADD_02 [9] | 0x50004064 | 2 | PC104 Header pin A29 |

| ISA_ADD_03 [9] | 0x50004064 | 3 | PC104 Header pin A28 |

| ISA_ADD_04 [9] | 0x50004064 | 4 | PC104 Header pin A27 |

| ISA_ADD_05 [9] | 0x50004064 | 5 | PC104 Header pin A26 |

| ISA_ADD_06 [9] | 0x50004064 | 6 | PC104 Header pin A25 |

| ISA_ADD_07 [9] | 0x50004064 | 7 | PC104 Header pin A24 |

| ISA_ADD_08 [9] | 0x50004064 | 8 | PC104 Header pin A23 |

| ISA_ADD_09 [9] | 0x50004064 | 9 | PC104 Header pin A22 |

| ISA_ADD_10 [9] | 0x50004064 | 10 | PC104 Header pin A21 |

| ISA_ADD_11 [9] | 0x50004064 | 11 | PC104 Header pin A20 |

| ISA_ADD_12 [9] | 0x50004064 | 12 | PC104 Header pin A19 |

| ISA_ADD_13 [9] | 0x50004064 | 13 | PC104 Header pin A18 |

| ISA_ADD_14 [9] | 0x50004064 | 14 | PC104 Header pin A17 |

| ISA_ADD_15 [9] | 0x50004064 | 15 | PC104 Header pin A16 |

| ISA_ADD_16 [9] | 0x5000406C | 0 | PC104 Header pin A15 |

| ISA_ADD_17 [9] | 0x5000406C | 1 | PC104 Header pin A14 |

| ISA_ADD_18 [9] | 0x5000406C | 2 | PC104 Header pin A13 |

| ISA_ADD_19 [9] | 0x5000406C | 3 | PC104 Header pin A12 |

| ISA_IOR [9] | 0x5000406C | 4 | PC104 Header pin B14 |

| ISA_IOW [9] | 0x5000406C | 5 | PC104 Header pin B13 |

| ISA_MEMR [9] | 0x5000406C | 6 | PC104 Header pin B12 |

| ISA_MEMW [9] | 0x5000406C | 7 | PC104 Header pin B11 |

I2C GPIO Expander

This GPIO controller is based on a PCA9555 I2C GPIO expander which provides up to 16 GPIO spread across two ports of 8 pins.

| Schematic Net Name | I2C Bus | I2C Device Address | GPIO Port | GPIO Pin | Location |

|---|---|---|---|---|---|

| ISA_CN_D03 | 2 | 0x20 | 0 | 0 | PC104 Header pin D03 |

| ISA_CN_D04 | 2 | 0x20 | 0 | 1 | PC104 Header pin D04 |

| ISA_CN_D05 | 2 | 0x20 | 0 | 2 | PC104 Header pin D05 |

| ISA_CN_D06 | 2 | 0x20 | 0 | 3 | PC104 Header pin D06 |

| ISA_CN_D07 | 2 | 0x20 | 0 | 4 | PC104 Header pin D07 |

| ISA_CN_D08 | 2 | 0x20 | 0 | 5 | PC104 Header pin D08 |

| ISA_CN_D09 | 2 | 0x20 | 0 | 6 | PC104 Header pin D09 |

| ISA_CN_D10 | 2 | 0x20 | 0 | 7 | PC104 Header pin D10 |

| ISA_CN_D11 | 2 | 0x20 | 1 | 0 | PC104 Header pin D11 |

| ISA_CN_D12 | 2 | 0x20 | 1 | 1 | PC104 Header pin D12 |

| ISA_CN_D13 | 2 | 0x20 | 1 | 2 | PC104 Header pin D13 |

| ISA_CN_D14 | 2 | 0x20 | 1 | 3 | PC104 Header pin D14 |

| ISA_CN_D15 | 2 | 0x20 | 1 | 4 | PC104 Header pin D15 |

- ↑ 1.0 1.1 1.2 1.3 1.4 This is controlled automatically on startup to give the SD card a clean reset, but otherwise this should not be toggled manually.

- ↑ default is input with pulldown (0). If driven high, this MUXes the bottom port of the dual high USB port to the XBee header. If low or input, no USB is present on this header. This USB is needed for cell modules, but interferes with older serial modules where these USB pins are reserved. See your XBee/Skywire device's datasheet to verify if USB is needed.

- ↑ This is handled automatically on startup

- ↑ 4.0 4.1 See /sys/class/leds/ for interacting with these LEDs rather than toggling the GPIO directly.

- ↑ High by default. This allows power cycling USB peripherals in the field.

- ↑ Ethernet PHY and USB hub reset. This is automatically controlled during startup and should not be toggled.

- ↑ This pin is input only

- ↑ 8.0 8.1 8.2 This pin cannot be controlled as a GPIO until Syscon 0x08 bit 10 is set

- ↑ 9.00 9.01 9.02 9.03 9.04 9.05 9.06 9.07 9.08 9.09 9.10 9.11 9.12 9.13 9.14 9.15 9.16 9.17 9.18 9.19 9.20 9.21 9.22 9.23 9.24 9.25 9.26 9.27 9.28 9.29 9.30 9.31 9.32 9.33 9.34 9.35 9.36 9.37 9.38 9.39 9.40 This pin cannot be controlled as a GPIO until Syscon 0x08 bit 8 is set

- ↑ This is used to detect if the Mikrobus socket is reversed.

- ↑ This pin cannot be controlled as a GPIO until Syscon 0x08 bit 6 is set

- ↑ 12.0 12.1 12.2 12.3 This pin cannot be controlled as a GPIO until Syscon 0x08 bit 4 is set

- ↑ 13.0 13.1 This pin cannot be controlled as a GPIO until Syscon 0x08 bit 7 is set

- ↑ 14.0 14.1 This pin cannot be controlled as a GPIO until Syscon 0x08 bit 5 is set

eMMC

This platform includes a soldered down eMMC flash device for on-board non-volatile storage. Our standard platform configurations use a 4 GB eMMC device, but up to 64 GB are available for customized builds. The eMMC device includes additional boot partitions that are used by U-Boot and are not affected by the disk's partition table.

See the software manual for the software image in use (boy that needs to be worded better) for more information.

ADD DETAILS ON SPEEDS

The default disk layout is as follows:

| Device | Contents |

|---|---|

| /dev/mmcblk0 | eMMC block device |

| /dev/mmcblk0boot0 | U-Boot |

| /dev/mmcblk0boot1 | Unused |

| /dev/mmcblk0p1 | Full Debian Linux partition |

SHOULD THIS MANUAL TALK ABOUT ENH MODES? CREATE ANOTHER MANUAL FOR IT?

Ethernet Ports

The i.MX6UL CPU contains two 10/100 Mbit Ethernet controllers. These are located at the two Ethernet connector jacks on the platform.

The i.MX6UL CPU Ethernet ports support IEEE 1588 Precision Time Protocol (PTP), both Version 1 and 2 (PTPv1 & PTPv2). This allows synchronizing the system clock to within ±1 us across multiple devices on the same network.

See the software manual for the software image in use (boy that needs to be worded better) for more information on utilizing the interfaces as well as setting up PTP.

Ferroelectric RAM (FRAM)

| Note: | FRAM is not present on the TS-7250-V3-SMN1I or TS-7250-V3-SMN2I configurations. |

This device supports an optional 2 KiB of non-volatile Ferroelectric RAM (FRAM) connected to the CPU via SPI. FRAM is non-volatile, incredibly fast to write, and is specified with 1 trillion read/write cycles per each byte with a 200 year data retention. Reads of data from FRAM is a destructive process -- the FRAM's internal controller handles data write-back after a read. Care should be taken to prevent sudden power-off events during both reads and writes of FRAM.

The FRAM is connected to the TS-7250-V3 on SPI bus 4, chip-select 1.

See the software manual for the software image in use (boy that needs to be worded better) for information on interacting with the device.

I2C

The i.MX6UL supports I2C at 100 kHz, or using fast mode for 400 kHz operation. The TS-7250-V3 uses two CPU I2C busses for onboard device, and an FPGA I2C controller for the mikroBUS I2C interface.

See the software manual for the software image in use (boy that needs to be worded better) for more information.

SHOULD WE LIST DEVICE NODES OR BUS NUMBERS/FIRST BUS/SECOND BUS/ETC?

| I2C Bus | Address | Description |

|---|---|---|

| i2c0 | 0x1e | Magnetometer |

| 0x54 | Supervisory Microcontroller | |

| 0x68 | RTC | |

| 0x6a | IMU | |

| i2c1 | 0x20 | NXP pca9555 GPIO expander (Chip 2-0020) |

| 0x64 | ATSHA204 LINK TO MORE INFO [1] |

- ↑ Not populated by default

TODO: Add mikroBUS I2C notes

Inertial Measurement Unit (IMU)

Linux provides access to the various IMU components through the IIO subsystem (via iio-tools and libiio).

Accelerometer (ST ISM330)

This platform features an ST accelerometer / gyroscope. The accelerometer has an acceleration range of ±2/±4/±8/±16 g.

Early units were built using the "ism330dlc", and newer units are built using the "ism330dhcx". These are functionally the same and provide the same channels and performance, but IIO requires you to specify the part number. Our example python/c code will show how to work with either.

The accelerometer is accessed through IIO with channels:

- accel_x

- accel_y

- accel_z

- timestamp

For example:

# ISM330DHCX

iio_attr -c ism330dhcx_accel accel_x

iio_attr -c ism330dhcx_accel accel_y

iio_attr -c ism330dhcx_accel accel_z

# ISM330DLC

iio_attr -c ism330dlc_accel accel_x

iio_attr -c ism330dlc_accel accel_y

iio_attr -c ism330dlc_accel accel_z

The below examples will be written for the ism330dhcx_accel, but if this fails instead use the ism330dlc_accel device. These commands will provide a single sample of all of the values:

root@tsimx6ul:~# iio_attr -c ism330dhcx_accel accel_x dev 'ism330dhcx_accel', channel 'accel_x' (input), attr 'injection_raw', ERROR: Permission denied (-13) dev 'ism330dhcx_accel', channel 'accel_x' (input), attr 'raw', value '-183' dev 'ism330dhcx_accel', channel 'accel_x' (input), attr 'scale', value '0.000598' dev 'ism330dhcx_accel', channel 'accel_x' (input), attr 'scale_available', value '0.000598 0.001196 0.002392 0.004785' root@tsimx6ul:~# iio_attr -c ism330dhcx_accel accel_y dev 'ism330dhcx_accel', channel 'accel_y' (input), attr 'injection_raw', ERROR: Permission denied (-13) dev 'ism330dhcx_accel', channel 'accel_y' (input), attr 'raw', value '-292' dev 'ism330dhcx_accel', channel 'accel_y' (input), attr 'scale', value '0.000598' dev 'ism330dhcx_accel', channel 'accel_y' (input), attr 'scale_available', value '0.000598 0.001196 0.002392 0.004785' root@tsimx6ul:~# iio_attr -c ism330dhcx_accel accel_z dev 'ism330dhcx_accel', channel 'accel_z' (input), attr 'injection_raw', ERROR: Permission denied (-13) dev 'ism330dhcx_accel', channel 'accel_z' (input), attr 'raw', value '16491' dev 'ism330dhcx_accel', channel 'accel_z' (input), attr 'scale', value '0.000598' dev 'ism330dhcx_accel', channel 'accel_z' (input), attr 'scale_available', value '0.000598 0.001196 0.002392 0.004785'

To get the real world value, multiply the scale * the raw value. In this case:

- X: -0.109434 g

- Y: -0.174616 g

- Z: 9.861618 g

The default scale is ±2, but ±2/±4/±8/±16 can be selected by setting the scale:

dev 'ism330dhcx_accel', channel 'accel_z' (input), attr 'scale', value '0.000598' dev 'ism330dhcx_accel', channel 'accel_z' (input), attr 'scale_available', value '0.000598 0.001196 0.002392 0.004785'

To set ±4, you would write the second available scale:

iio_attr -c ism330dhcx_accel accel_x scale 0.001196

The scale values are not independent on this device, and setting x/y/z will set the scale for all 3.

This driver also supports pulling continuous samples using the buffer interface. These can be accessed using iio_readdev:

iio_readdev ism330dhcx_accel -T 0 -s 128 > samples.bin

The format of this file is specified with iio_attr:

root@tsimx6ul:~# iio_attr -c ism330dhcx_accel dev 'ism330dhcx_accel', channel 'accel_x' (input, index: 0, format: le:S16/16>>0), found 4 channel-specific attributes dev 'ism330dhcx_accel', channel 'accel_y' (input, index: 1, format: le:S16/16>>0), found 4 channel-specific attributes dev 'ism330dhcx_accel', channel 'accel_z' (input, index: 2, format: le:S16/16>>0), found 4 channel-specific attributes dev 'ism330dhcx_accel', channel 'timestamp' (input, index: 3, format: le:S64/64>>0), found 0 channel-specific attributes

The samples are padded to the nearest 8-bytes, so this means the binary format is:

| Bits | Description |

|---|---|

| 15:0 | accel_x, little endian, signed |

| 15:0 | accel_y, little endian, signed |

| 15:0 | accel_z, little endian, signed |

| 63:0 | timestamp, little endian, signed |

| 15:0 | Padding |

The unix utility hexdump supports formatting options which can parse these fields:

root@tsimx6ul:~# hexdump samples.bin --format '1/2 "X:%d " 1/2 "Y:%d " 1/2 "Z:%d " 1/8 "TS:%d" 1/2 "" "\n"' | head -n 4 X:-95 Y:-163 Z:8221 TS:200185381271666439 X:-107 Y:-147 Z:8248 TS:200190332264480519 X:-100 Y:-155 Z:8263 TS:200195283888013063 X:-95 Y:-159 Z:8253 TS:200200232540667655

This gives the raw values which can then be multiplied by the scale to get the real world value.

The IIO library can also be used to fill buffers with samples for processing. For example:

#!/usr/bin/env python3

import struct

import iio

ctx = iio.Context('local:')

ctx.set_timeout(0)

dev = ctx.find_device('ism330dhcx_accel') or ctx.find_device('ism330dlc_accel')

with open(f'/sys/bus/iio/devices/{dev.id}/sampling_frequency', 'w') as f:

f.write(f"833.000")

for chan_name in ["accel_x", "accel_y", "accel_z"]:

chn = dev.find_channel(chan_name)

chn.enabled = True

# We will request 64 samples at a time

buffer = iio.Buffer(dev, 64, False)

# sample size (3x 16-bit signed data)

sample_size = 6

# Refill and process the buffer

buffer.refill()

data = buffer.read()

for i in range(0, len(data), sample_size):

if i + sample_size <= len(data):

x, y, z = struct.unpack('<hhh', data[i:i+sample_size])

print(f' accel_x={x}, accel_y={y}, accel_z={z}')

for chn in dev.channels:

chn.enabled = False

This can also be done using the C library:

#include <stdio.h>

#include <stdlib.h>

#include <string.h>

#include <iio.h>

#define NUM_CHANNELS 3

#define SAMPLE_SIZE 6 // 3x 16-bit signed data (2 bytes per axis)

void process_samples(struct iio_buffer *buffer, size_t sample_size) {

char *data = iio_buffer_start(buffer);

size_t buffer_size = iio_buffer_end(buffer) - iio_buffer_start(buffer);

int16_t x, y, z;

for (size_t i = 0; i < buffer_size; i += sample_size) {

memcpy(&x, &data[i], sizeof(x));

memcpy(&y, &data[i + sizeof(x)], sizeof(y));

memcpy(&z, &data[i + 2 * sizeof(x)], sizeof(z));

printf("accel_x=%d, accel_y=%d, accel_z=%d\n", x, y, z);

}

}

int main() {

struct iio_context *ctx;

struct iio_device *dev;

struct iio_channel *channels[NUM_CHANNELS];

struct iio_buffer *buffer;

const char *channel_names[NUM_CHANNELS] = { "accel_x", "accel_y", "accel_z" };

// Create context and find device

ctx = iio_create_local_context();

if (!ctx || !(dev = iio_context_find_device(ctx, "ism330dhcx_accel")) &&

!(dev = iio_context_find_device(ctx, "ism330dlc_accel"))) {

fprintf(stderr, "Unable to create context or find device\n");

iio_context_destroy(ctx);

return 1;

}

// Enable channels and set sampling frequency

for (int i = 0; i < NUM_CHANNELS; i++) {

channels[i] = iio_device_find_channel(dev, channel_names[i], false);

if (!channels[i] || iio_channel_attr_write(channels[i], "sampling_frequency", "833.000") < 0) {

fprintf(stderr, "Unable to find or configure channel %s\n", channel_names[i]);

iio_context_destroy(ctx);

return 1;

}

iio_channel_enable(channels[i]);

}

// Create buffer and process samples

buffer = iio_device_create_buffer(dev, 64, false);

if (!buffer || iio_buffer_refill(buffer) < 0) {

fprintf(stderr, "Unable to create or refill buffer\n");

iio_context_destroy(ctx);

return 1;

}

process_samples(buffer, SAMPLE_SIZE);

// Cleanup

iio_buffer_destroy(buffer);

iio_context_destroy(ctx);

return 0;

}

Gyroscope (ST ISM330)

This platform features an ST accelerometer / gyroscope. The gyroscope has a selectable angular range of ±125/±250/±500/±1000/±2000 dps

Early units were built using the "ism330dlc", and newer units are built using the "ism330dhcx". These are functionally the same and provide the same channels and performance, but IIO requires you to specify the part number. Our example python/c code will show how to work with either.

The gyroscope is accessed through IIO with channels:

- anglvel_x

- anglvel_y

- anglvel_z

- timestamp

For example:

# ISM330DHCX

iio_attr -c ism330dhcx_gyro anglvel_x

iio_attr -c ism330dhcx_gyro anglvel_y

iio_attr -c ism330dhcx_gyro anglvel_z

# ISM330DLC

iio_attr -c ism330dlc_gyro anglvel_x

iio_attr -c ism330dlc_gyro anglvel_y

iio_attr -c ism330dlc_gyro anglvel_z

root@tsimx6ul:~# iio_attr -c ism330dhcx_gyro anglvel_x dev 'ism330dhcx_gyro', channel 'anglvel_x' (input), attr 'raw', value '2359' dev 'ism330dhcx_gyro', channel 'anglvel_x' (input), attr 'scale', value '0.000153' dev 'ism330dhcx_gyro', channel 'anglvel_x' (input), attr 'scale_available', value '0.000153 0.000305 0.000611 0.001222' root@tsimx6ul:~# iio_attr -c ism330dhcx_gyro anglvel_y dev 'ism330dhcx_gyro', channel 'anglvel_y' (input), attr 'raw', value '-1667' dev 'ism330dhcx_gyro', channel 'anglvel_y' (input), attr 'scale', value '0.000153' dev 'ism330dhcx_gyro', channel 'anglvel_y' (input), attr 'scale_available', value '0.000153 0.000305 0.000611 0.001222' root@tsimx6ul:~# iio_attr -c ism330dhcx_gyro anglvel_z dev 'ism330dhcx_gyro', channel 'anglvel_z' (input), attr 'raw', value '2761' dev 'ism330dhcx_gyro', channel 'anglvel_z' (input), attr 'scale', value '0.000153' dev 'ism330dhcx_gyro', channel 'anglvel_z' (input), attr 'scale_available', value '0.000153 0.000305 0.000611 0.001222'

This shows a snapshot of the x, y, z values. To get the real world value, multiply the scale * the raw value. In this case:

- X: 0.360927 dps

- Y: -0.255051 dps

- Z: 0.422433 dps

The default scale is ±250, but ±250/±500/±1000/±2000 can be selected by setting the scale:

dev 'ism330dhcx_gyro', channel 'anglvel_z' (input), attr 'scale', value '0.000153' dev 'ism330dhcx_gyro', channel 'anglvel_z' (input), attr 'scale_available', value '0.000153 0.000305 0.000611 0.001222'

To set ±1000, you would write the third available scale:

iio_attr -c ism330dhcx_gyro anglvel_z scale 0.000611

The scale values are not independent on this device, and setting x/y/z will set the scale for all 3.

This driver also supports pulling continuous samples using the buffer interface. These can be accessed using iio_readdev:

iio_readdev ism330dhcx_gyro -T 0 -s 128 > samples.bin

The format of this file is specified with iio_attr:

root@tsimx6ul:~# iio_attr -c ism330dhcx_gyro dev 'ism330dlc_gyro', channel 'anglvel_x' (input, index: 0, format: le:S16/16>>0), found 3 channel-specific attributes dev 'ism330dlc_gyro', channel 'anglvel_y' (input, index: 1, format: le:S16/16>>0), found 3 channel-specific attributes dev 'ism330dlc_gyro', channel 'anglvel_z' (input, index: 2, format: le:S16/16>>0), found 3 channel-specific attributes dev 'ism330dlc_gyro', channel 'timestamp' (input, index: 3, format: le:S64/64>>0), found 0 channel-specific attributes

The samples are padded to the nearest 8-bytes, so this means the binary format is:

| Bits | Description |

|---|---|

| 15:0 | anglvel_x, little endian, signed |

| 15:0 | anglvel_y, little endian, signed |

| 15:0 | anglvel_z, little endian, signed |

| 63:0 | timestamp, little endian, signed |

| 15:0 | Padding |

The unix utility hexdump supports formatting options which can parse these fields into their raw values:

root@tsimx6ul:~# hexdump samples.bin --format '1/2 "X:%d " 1/2 "Y:%d " 1/2 "Z:%d " 1/8 "TS:%d" 1/2 "" "\n"' | head -n 40 X:-58 Y:-199 Z:24 TS:419695978925948679 X:-67 Y:-196 Z:29 TS:419701023781322503 X:-64 Y:-197 Z:28 TS:419705968690298631 X:-58 Y:-203 Z:29 TS:419711008204553991

The IIO library can also be used to fill buffers with samples for processing. For example:

#!/usr/bin/env python3

import struct

import iio

ctx = iio.Context('local:')

ctx.set_timeout(0)

dev = ctx.find_device('ism330dhcx_gyro') or ctx.find_device('ism330dlc_gyro')

with open(f'/sys/bus/iio/devices/{dev.id}/sampling_frequency', 'w') as f:

f.write(f"833.000")

for chan_name in ["anglvel_x", "anglvel_y", "anglvel_z"]:

chn = dev.find_channel(chan_name)

chn.enabled = True

# We will request 64 samples at a time

buffer = iio.Buffer(dev, 64, False)

# sample size (3x 16-bit signed data)

sample_size = 6

# Refill and process the buffer

buffer.refill()

data = buffer.read()

for i in range(0, len(data), sample_size):

if i + sample_size <= len(data):

x, y, z = struct.unpack('<hhh', data[i:i+sample_size])

print(f' anglvel_x={x}, anglvel_y={y}, anglvel_z={z}')

for chn in dev.channels:

chn.enabled = False

This can also be done using the C library:

#include <stdio.h>

#include <stdlib.h>

#include <string.h>

#include <iio.h>

#define NUM_CHANNELS 3

#define SAMPLE_SIZE 6 // 3x 16-bit signed data (2 bytes per axis)

void process_samples(struct iio_buffer *buffer, size_t sample_size) {

char *data = iio_buffer_start(buffer);

size_t buffer_size = iio_buffer_end(buffer) - iio_buffer_start(buffer);

int16_t x, y, z;

for (size_t i = 0; i < buffer_size; i += sample_size) {

memcpy(&x, &data[i], sizeof(x));

memcpy(&y, &data[i + sizeof(x)], sizeof(y));

memcpy(&z, &data[i + 2 * sizeof(x)], sizeof(z));

printf("anglvel_x=%d, anglvel_y=%d, anglvel_z=%d\n", x, y, z);

}

}

int main() {

struct iio_context *ctx;

struct iio_device *dev;

struct iio_channel *channels[NUM_CHANNELS];

struct iio_buffer *buffer;

const char *channel_names[NUM_CHANNELS] = { "anglvel_x", "anglvel_y", "anglvel_z" };

// Create context and find device

ctx = iio_create_local_context();

if (!ctx || !(dev = iio_context_find_device(ctx, "ism330dhcx_gyro")) &&

!(dev = iio_context_find_device(ctx, "ism330dlc_gyro"))) {

fprintf(stderr, "Unable to create context or find device\n");

iio_context_destroy(ctx);

return 1;

}

// Enable channels and set sampling frequency

for (int i = 0; i < NUM_CHANNELS; i++) {

channels[i] = iio_device_find_channel(dev, channel_names[i], false);

if (!channels[i] || iio_channel_attr_write(channels[i], "sampling_frequency", "833.000") < 0) {

fprintf(stderr, "Unable to find or configure channel %s\n", channel_names[i]);

iio_context_destroy(ctx);

return 1;

}

iio_channel_enable(channels[i]);

}

// Create buffer and process samples

buffer = iio_device_create_buffer(dev, 64, false);

if (!buffer || iio_buffer_refill(buffer) < 0) {

fprintf(stderr, "Unable to create or refill buffer\n");

iio_context_destroy(ctx);

return 1;

}

process_samples(buffer, SAMPLE_SIZE);

// Cleanup

iio_buffer_destroy(buffer);

iio_context_destroy(ctx);

return 0;

}

Magnetometer (ST IIS2MDCTR)

This platform includes an ST IIS2MDCTR 3-axis magnetometer, which has a magnetic field dynamic range of ±50 gauss (16 bits of precision at up to 150 Hz).

The magnetometer is accessed through Linux's industrial I/O (IIO) subsystem as lis2mdl with channels:

- magn_x

- magn_y

- magn_z

- timestamp

For example:

root@tsimx6ul:~# iio_attr -c lis2mdl -c magn_x dev 'lis2mdl', channel 'magn_x' (input), attr 'raw', value '630' dev 'lis2mdl channel 'magn_x' (input), attr 'scale', value '0.001500' root@tsimx6ul:~# iio_attr -c lis2mdl -c magn_y dev 'lis2mdl channel 'magn_y' (input), attr 'raw', value '-165' dev 'lis2mdl channel 'magn_y' (input), attr 'scale', value '0.001500' root@tsimx6ul:~# iio_attr -c lis2mdl -c magn_z dev 'lis2mdl channel 'magn_z' (input), attr 'raw', value '9' dev 'lis2mdl channel 'magn_z' (input), attr 'scale', value '0.001500'

This shows a snapshot of the x, y, z values. To get the measured field strength along each axis, multiply the scale by the raw value to get the actual reading in milligauss. In the above example:

- X: 0.945 mG (milligauss)

- Y: -0.2475 mG

- Z: 0.0135 mG

Interrupts

| Note: | This section is incomplete at this time. |

LEDs

This platform has two on-board LEDs near the 5 V power input and PC/104 header; a green LED and a red LED. U-Boot uses these to indicate stages of boot and different kernels may use these LEDs for different purposes while also allowing user control of them.

See the relevant software manual for more information on controlling the LEDs.

MicroSD Interface

The i.MX6UL SDHCI driver supports microSD cards up to and including microSDXC standards, supporting up to 2 TB of storage.

TALK ABOUT SPEEDS

Appears at /dev/mmcblk1

We have performed compatibility testing on the Sandisk MicroSD cards we provide. We do not suggest switching brands/models without your own qualification testing. While SD cards specifications are standardized, in practice cards behave very differently. We do not recommend ATP or Transcend MicroSD cards due to known compatibility issues. IS THIS STILL AN ISSUE?!

MicroSD cards should not have power removed during a write or they will have disk corruption. Keep the filesystem mounted read only if this is a possibility. It is not always possible for fsck to recover from the types of failures that will be seen with SD power loss. Consider using the eMMC for storage instead which is far more resilient to power loss.

Supervisory Microcontroller

| Note: | The supervisory features are only supported in kernel 5.10 and later, and on PCB revision C (early 2023) and later. |

The TS-7250-V3 includes a preprogrammed microcontroller intended to manage the SBC's power state, RTC, and a few additional ADCs to monitor system rails. This microcontroller also provides the USB console functionality. The way console is routed can be changed from /sys/:

root@tsimx6ul:~# cat /sys/bus/i2c/devices/0-0010/console_cfg [auto] always-usb

| Setting | Description |

|---|---|

| auto | Console routes to DB9 by default, but if a USB cable is connected to the microcontroller it routes here instead. |

| always-usb | Console does not route to db9, and is only available on USB. |

This can be written to /sys/, and will persist between reboots:

echo "always-usb" > /sys/bus/i2c/devices/0-0010/console_cfg

Anytime console is routed to USB instead, ttyS8 is routed to the DB9 port instead for application use.

Supervisory Microcontroller Low Power Mode

To achieve the lowest power sleep state, the kernel is configured with the reset controller driver, ts_supervisor_rstc. This driver implements shutdown for the SBC to enter the low power state. For example, shutdown -h now will cause a proper shutdown of the CPU with the last step of this issuing a command to the Supervisory Microcontroller to remove power from the whole platform. The Supervisory Microcontroller will remain in a lower power state until one of the following events occurs. At which time it will wake up and enable power to the rest of the platform to let it begin a normal boot process.

- CN8 ADC Header pin 9 has 3-30 V applied.

- 5 V goes below 4.7 V, and then back above 4.7 V.

- RTC Alarm occurs

- USB Console connected

In this low power state, the entire platform draws approximately 25 mW. The wakeup source can be detected from the reset reasons.

Supervisory Microcontroller Reset Reasons

The supervisory microcontroller can detect multiple reasons why the system rebooted or woke back up. These are provided by the sysfs device:

root@tsimx6ul:~# cat /sys/bus/platform/devices/tssupervisor-reset/reboot_reason POR

| reboot_reason text | Description |

|---|---|

| POR | Initial power-on reset after both micro USB serial console and VIN[1] were removed |

| Brownout | 5 VDC rail[2] dropped below 4.7 V but Supervisory Microcontroller power input remained valid |

| CPU WDT | Watchdog timer (WDT) expired and caused a hardware reboot |

| Software Reboot | The operating system initiated a reboot |

| RTC Alarm Reboot | Real-time clock (RTC) alarm expired and was configured to cause a hardware reboot |

| Wake from PWR Cycle | The operating system initiated a power-off, after which VIN[1] was cycled off and back on |

| Wake from WAKE_EN | The operating system initiated a power-off, after which the voltage input on ADC Header pin 9 rose from below 1 V to above 3 V |

| Wake from USB VBUS | The operating system initiated a power-off, after which a micro USB serial console cable was connected to USB host |

| Wake from RTC Alarm | The operating system initiated a power-off, after which the real-time clock (RTC) alarm expired |

Supervisory Microcontroller RTC

The supervisory microcontroller also provides a real time clock to backup system time when power is lost. This RTC features:

- Unsigned 32-bit counter

- Alarm to wake the board up from power off

- Alarm can be configured as a slow watchdog

- Battery detection

- Offset support to tune rtc in ppb

- Can retain time for ~8 years with the CR1632 battery

The typical RTC features are provided by the rtc-tssupervisor driver present in our kernels. This includes setting/getting the latest epoch time. On most distributions this requires no user interaction and systemd will sync the hardware clock when it syncs to a network time protocol (NTP) server.

To manually interact with the RTC the hwclock command is typically used:

# Set the RTC from the system time

hwclock --systohc

# Set the system time from the RTC

hwclock --hctosys

# Just print the RTC time, do not set either clock

hwclock --show

Our RTC also has several sysfs entries to support the nonstandard features:

### VBATT:

## Returns 0 or 1 to indicate if VBATT is > 1.8-2.0V

## Does not indicate a sufficient voltage to keep time, but can be used to detect

## no battery or a malfunctioning battery

## This is only checked on power on

cat /sys/class/rtc/rtc0/device/batt_present

### RTC Alarm Wake up:

## The RTC can be used to wake the system after shutting down.

# The hwclock call can be skipped if system time is already set:

hwclock --systohc

# Takes the current time and adds 60 seconds

echo $(($(date +%s)+60)) > /sys/class/rtc/rtc0/device/alarm

echo 1 > /sys/class/rtc/rtc0/device/alarm_en

shutdown -h now

# The system will go into the low power state, and power back up when the alarm expires.

### RTC Alarm Watchdog:

## If its not being used for waking the system, the RTC alarm can be used to

## Reset the system if the time is not updated. This can be used as a very slow watchdog, setting

## a reset time of minutes/hours/days ahead instead of a typical 128 seconds a typical

## watchdog allows as the largest timer, but it is slower to feed so it should not be fed quickly.

## Keep in mind this reset is immediate and can corrupt any filesystems mounted read/write when the watchdog

## trips.

# The hwclock call can be skipped if system time is already set:

hwclock --systohc

# Takes the current time and adds 10 seconds

echo $(($(date +%s)+10)) > /sys/class/rtc/rtc0/device/alarm

echo 1 > /sys/class/rtc/rtc0/device/alarm_cause_reboot

echo 1 > /sys/class/rtc/rtc0/device/alarm_en

A typical RTC crystal is approximately ±20 ppm accurate which results in drift while the system is offline of approximately ±631 seconds per year. Our circuit, operating temperature, crystal age (~±3 ppm per year), all influence the accuracy of the crystal. An NTP client like chrony can be used to determine the PPM offset at a board at a given temperature, and the RTC can automatically apply this offset correction. This relies on having access to an accurate NTP server to calibrate the RTC.

Eg, on Debian:

apt-get update && apt-get install chrony -y

In case there was a previous offset applied which may affect the calibration:

echo 0 > /sys/class/rtc/rtc0/offset

Open /etc/chrony/chrony.conf, and add the line:

rtcfile /var/lib/chrony/rtcfile

Make sure there is no 'rtcsync' in the file since it cannot sync the hardware clock during this test, and that cannot be set with rtcfile.

Then restart chrony, and force a sync:

service chrony restart

chronyc makestep

At this step we must wait for the system clock to get in sync with the upstream NTP server. From our testing with a good network connection this can take 15-30 minutes until the RTC offset settles. From here we can query chrony for the RTC offset.

root@tsimx6:~# chronyc rtcdata RTC ref time (UTC) : Fri Nov 18 13:38:36 2022 Number of samples : 64 Number of runs : 40 Sample span period : 254m RTC is fast by : -0.198639 seconds RTC gains time at : -21.674 ppm

In this example, the RTC is offset is -21.674 ppm. Linux expects this value to be in parts per billion, and it should be indicated what value will correct the crystal. Multiply the ppm by 1000 * -1 to get a value we can write to the offsets file. For example:

# Parse rtcdata and get the PPM value

# Eg, with the above example this is:

# PPM=-21.674

PPM=$(chronyc rtcdata | grep ppm | awk '{print $6}')

# Convert to parts per billion and invert the value to apply a correction.

# Eg, with the above example this is:

# PPB_CORRECTION=21674

PPB_CORRECTION=$(echo "scale=0; ${PPM}*-1000/1" | bc)

echo $PPB_CORRECTION > /sys/class/rtc/rtc0/offset

Once this is calibrated at a given temperature the ppm offset range can be calculated with:

0.035 * (CalibrationTemp - OperatingTemp)^2

For example, if the RTC is calibrated to the offset at 22C:

0.035*(22-85)^2=138.915

, or roughly ±139 ppm at 85 C.

To calculate the seconds drift per year with this PPM offset:

(60*60*24*365)*(138.915*10^-6)=4380.8

Supervisory Microcontroller ADC

The supervisory microcontroller provides ADC channels to monitor onboard rails such as VIN, 5 V, 3.3 V, and more. Channels that are less than 3.3 V are provided directly by the IIO device "tssupervisor_adc". The analog frontend driver is used to rescale some channels to the range supported by this ADC.

| iio device | iio channel | Schematic name |

|---|---|---|

| an_3p3v | voltage0 | 3.3V |

| tssupervisor-adc | voltage1 | VDD_ARM_CAP |

| tssupervisor-adc | voltage2 | VDD_SOC_CAP |

| an_5v | voltage0 | 5V_A |

| an_8v_48v | voltage0 | 8V_48V |

These can be accessed from any language with iio bindings, from /sys/bus/iio/, or using iio_attr. For example, to reading the input voltage with iio_attr:

root@tsimx6ul:~# iio_attr -c an_8v_48v voltage0 dev 'an_8v_48v', channel 'voltage0' (input), attr 'raw', value '619' dev 'an_8v_48v', channel 'voltage0' (input), attr 'scale', value '18.650634765'

The raw and scale values can be used to get the real value in millivolts:

619*18.650634765 = 11544.742919535

or 11.54 V.

Supervisory Microcontroller Temp Sensor

The supervisory microcontroller provides a temperature sensor to read its die temperature as millicelcius.

| iio device | iio channel |

|---|---|

| tssupervisor-temp | temp |

These can be accessed from any language with iio bindings, from /sys/bus/iio/, or using iio_attr. For example, to reading the temperature with iio_attr:

root@tsimx6ul:~# iio_attr -c tssupervisor-temp temp dev 'tssupervisor-temp', channel 'temp' (input), attr 'input', value '32915'

This value would be 32.915C.

SPI

DISCUSS WILC SPI? I2C TALKS ABOUT ON-BOARD BUSSES THAT ARE OTHERWISE UNUSABLE? The TS-7250-V3 provides two SPI busses.

SPI devices are recommended to be connected to a kernel driver, though it is possible to arbitrarily interface to SPI devices using the spidev kernel interface. See the software manual for the software image in use (boy that needs to be worded better) for more information.

The TS-7250-V3 FPGA includes the 2 opencore SPI controllers. Under Linux these are spi4 and spi5.

SHOULD THIS MENTION DEVICE NODE NAMES/NUMBER/FIRST BUS/SECOND BUS/ETC?

| Controller | Chip select | Device |

|---|---|---|

| spi4 | 0 | /dev/spidev4.0 DIO Header SPI bus |

| 1 | Ferroelectric RAM (FRAM) | |

| 2 | FPGA Flash (/dev/mtdblock0) [1] | |

| spi5 | 0 | /dev/spidev5.0 mikroBUS SPI |

UARTs

The TS-7250-V3 includes UARTs on the CPU, as well as 16550A compatible registers on the FPGA interface.

See the software manual for the software image in use (boy that needs to be worded better) for more information.

THESE SHOULD INCLUDE MORE INFORMATION ON WHICH PHYSICAL INTERFACE THEY ARE. OTHER SECTIONS, LIKE GPIO, JUST KIND OF CALL OUT THE NET NAME AND LINK HERE BUT THERE IS NO LINK BETWEEN SOFTWARE ORDERING AND HARDWARE NAME.

| UART Dev. | Type | TX / + Loc. | RX / - Loc. | CTS | RTS | DCD | DTR | TXEN |

|---|---|---|---|---|---|---|---|---|

| ttymxc0 | USB Console | P2 MicroUSB | P2 MicroUSB | N/A | N/A | N/A | N/A | N/A |

| ttymxc2 | Bluetooth | Onboard | Onboard | N/A | N/A | N/A | N/A | N/A |

| ttymxc3 | 3.3V TTL | XBee pin 3 | XBee pin 2 | XBee pin 12 | N/A | N/A | N/A | N/A |

| ttyS8 | RS-232 | DB9 pin 3 | DB9 pin 2 | DB9 pin 8 | DB9 pin 7 | DB9 pin 1 | DB9 pin 4 | N/A |

| ttyS9 | RS-232 | COM2 pin 3 | COM2 pin 2 | COM2 pin 8 | COM2 pin 7 | N/A | N/A | N/A |

| ttyS10 | RS-232 | COM3 pin 3 | COM3 pin 2 | COM3 pin 8 | COM3 pin 7 | N/A | N/A | N/A |

| ttyS11 | RS-485 | COM2 pin 1 | COM2 pin 6 | N/A | N/A | N/A | N/A | N/A |

| ttyS12 | RS-485 | COM2 pin 4 | COM2 pin 9 | N/A | N/A | N/A | N/A | N/A |

| ttyS13 | TTL | mikroBUS pin 13 | mikroBUS pin 14 | N/A | N/A | N/A | N/A | N/A |

| ttyS14 [1] | TTL | DIO pin 5 | DIO pin 7 | N/A | N/A | N/A | N/A | DIO pin 13 |

| ttyS15 [1] | TTL | DIO pin 9 | DIO pin 11 | N/A | N/A | N/A | N/A | DIO pin 15 |

- ↑ 1.0 1.1 Not enabled until setting #FPGA Syscon 0x08 bit 9 to 1

The DIO header uarts, ttyS14 and ttyS15 are not enabled until a mux register is set.

# Change DIO header to use UARTs instead of GPIO

tshwctl --address 0x08 --poke32 0x6000

RS-485

RS-485 is implemented via a UART interface inside of the FPGA. This device handles automatic TXEN assertion and de-assertion for half-duplex RS-485 communication without any required settings or API calls. See the UARTs section for the location of the RS-485 port.

RS-422

While both ttyS11 and ttyS12 support RS-485 half duplex these uarts can also be used as a single full duplex RS-422. Either of these UARTs are electrically compatible with RS-485/RS-422 and support TX or RX. To implement RS-422 in software open either UART and use it for transmit, and open the other UART and only use it for receive.

USB

The TS-7250-V3 offers two USB 2.0 host ports. Power to the host ports can be controlled via GPIO EXPLAIN WHICH.

See the software manual for the software image in use (boy that needs to be worded better) for more information. NOTE THAT THERE MAY BE KERNEL DIFFERENCES! ORIGINAL MANUAL TALKS ABOUT STILL USING THE BRIGHTNESS FILE, WHEREAS IN 5.10/6.6 ITS A GPIO PROPERLY.

The USB A host port stack can provide 1 A total power output shared between the two ports.

Watchdog

The TS-7250-V3 implements a WDT inside the CPU. Our stock distribution uses the 'watchdog' utility to check system health, set feed length, and perform feeds. Setting a timeout of 0 and issuing a feed will disable the WDT in hardware.

The kernel driver supports the "Magic Close" feature of the WDT. This means that a 'V' character must be fed in to the watchdog file before the file is closed in order to disable the WDT. If this does not happen then the WDT is not stopped and it will continue it's countdown. This is the default behavior of our stock kernel.

Additionally, if the kernel is compiled with CONFIG_WATCHDOG_NOWAYOUT then the WDT can never be stopped once it is started at boot. This is not enabled by default in our stock kernel

See the Linux WDT API documentation for more information.

WiFi

This board uses an ATWILC3000-MR110CA IEEE 802.11 b/g/n Link Controller Module With Integrated Bluetooth® 4.0. Linux provides support for this module using the wilc3000 driver.

Summary features:

- IEEE 802.11 b/g/n RF/PHY/MAC SOC

- IEEE 802.11 b/g/n (1x1) for up to 72 Mbps PHY rate

- Single spatial stream in 2.4GHz ISM band

- Integrated PA and T/R Switch Integrated Chip Antenna

- Superior Sensitivity and Range via advanced PHY signal processing

- Advanced Equalization and Channel Estimation

- Advanced Carrier and Timing Synchronization

- Wi-Fi Direct and Soft-AP support

- Supports IEEE 802.11 WEP, WPA, and WPA2 Security

- Supports China WAPI security

- Operating temperature range of -40°C to +85°C

External Interfaces

ADC Header

The ADC header supports 5 channels of 0-30VDC ADC. Of these 5, 3 channels support sampling 0-20mA current loops. These channels are sampled from:

iio_attr -c 2198000.adc voltage0

iio_attr -c 2198000.adc voltage1

iio_attr -c 2198000.adc voltage5

iio_attr -c 2198000.adc voltage8

iio_attr -c 2198000.adc voltage9

See the ADC section for more details on sampling these pins.

| Signals | Pin Layout | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Battery Connector

The Battery-Backed Real-Time Clock (RTC) uses a removable CR1632 coin cell in a vertical mount holder. The cell is inserted from the top of the connector, with the positive lead oriented as in the photo below. Once inserted, metal tabs retain the cell. The cell can be removed by pushing the tabs to the side and pushing the cell up from the bottom of the connector.

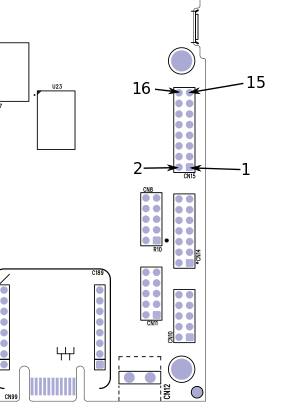

COM2 Header

The COM2 header is a 0.1" pitch 2x5 header supporting RS-485, RS-422 and RS-232.

| Signals | Pin Layout | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

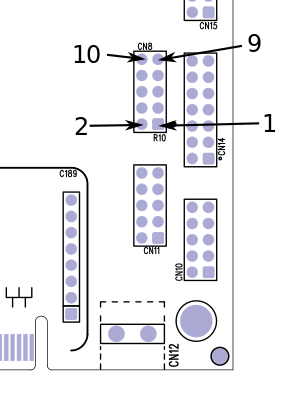

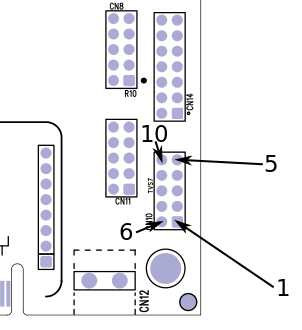

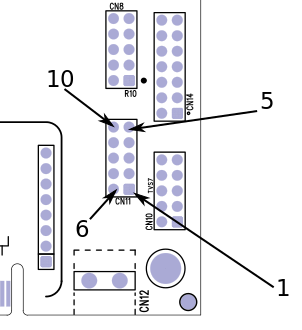

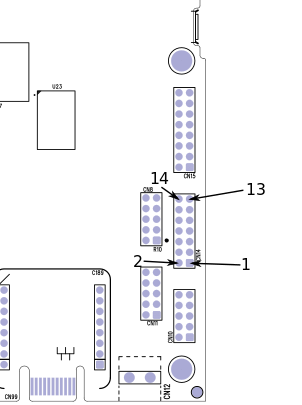

COM3 Header

The COM3 header is a 0.1" pitch 2x5 header supporting CAN and RS-232.

| Signals | Pin Layout | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

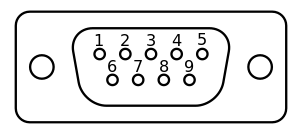

DB9 Connector

The DB9 (DE-9) connector provides an RS-232 port with full handshakes.

| Signals | Pin Layout | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

DIO Header

The DIO header is a 0.1" pitch 2x8 header including SPI and GPIO. All pins on this header are 5V tolerant except SPI output pins. The SPI input pins are 5V tolerant and can be connected to a 5V SPI device. All of these DIO include pullups.

To use the SPI pins on this header as GPIO instead, disable SPI by changing the FPGA Syscon 0x08 bit 10:

tshwctl -a 0x8 --poke32 0x400

The DIO header is designed to provide compatibility with the KPAD accessory. This is a 4x4 numerical keypad. This is supported in userspace with the keypad.c source code, or the "keypad" utility which is included in the shiping image.

This debounces presses to 50ms, and does not repeat when numbers are held. This will output a string containing the key that is pressed. Eg:

root@tsimx6:~# keypad 1 UP DOWN 2ND ENTER

Ethernet connectors

The TS-7250-V3 supports two independent 10/100 Ethernet ports. See the Configuring the Network section of the manual for more information on configuration.

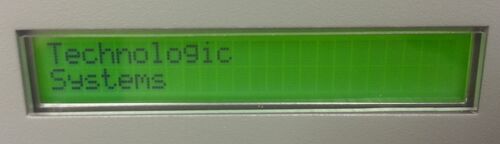

LCD Header

The LCD header is a 0.1" pitch 2x7 header including GPIO. This is designed around compatibility with the HD44780 LCD controller which includes our LCD-LED. The LCD Data pins (7-14) are 5V tolerant. These will output up to 3.3V, and the remaining control IO and PWM are 3.3V tolerant. The TS-7250-V3 Debian images include a command lcdmesg. This can be used to write to our LCD-LED display.

For example, this would write to the display:

lcdmesg "line 1" "line 2"

# Messages can also be piped to lcdmesg:

echo -e "line 1\nline 2\n" | lcdmesg

For example, running:

lcdmesg Technologic Systems

will display:

Pin 4, the LCD_BIAS pin, is used to set the contrast on the LCD.

tshwctl --address 0x1c --poke16 0x0 # Writes minimum

tshwctl --address 0x1c --poke16 0xf # Writes maximum

| Signals | Pin Layout | |||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

- ↑ PWM duty cycle controlled by FPGA Syscon reg 0x1c. This may need to be tuned depending on the environment or altitude where the display is used.

mikroBUS Header

The Mikrobus header is a 0.1" pitch 2x8 header which supports the Mikroe Click board ecosystem. This header features 3.3 V, 5 V, SPI, GPIO, ADC, PWM, a UART, and PWM. All I/O on this header are FPGA 3.3-V LVTTL.

The Click boards™ standard (where Click boards™ are a modular prototyping add-on board) is openly documented, allowing for custom boards to be designed.

By default all of these headers default to their non-gpio functions. These can be changed in the FPGA syscon register 0x08. For example:

# Make all mikrobus header pins GPIO:

memtool mw -l 0x50004008 0xF0

# Set only SPI to GPIO:

memtool mw -l 0x50004008 0x10

| Signals | Pin Layout | |||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

MicroSD Connector

The MicroSD socket is located near the DB9 on top of the board. See the #MicroSD Interface section for more details on the CPU controller.

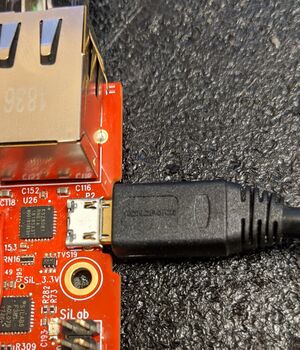

MicroUSB Connector

The TS-7250-V3 features an onboard supervisory microcontroller that converts the onboard 3.3V TTL console UART (ttymxc0) into a CP2103 USB serial device.

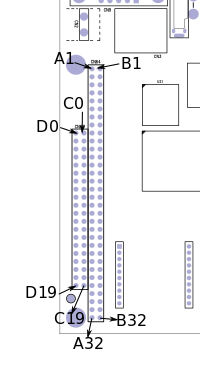

PC104 Header

The PC/104 connector consists of four rows of pins labelled A-D. This header implements the #PC104 Bus, and optionally most pins can be GPIO.

Refer to the IO specifications for details on the IO voltages of these pins. Not all pins on the PC/104 bus are designed to be 5V tolerant, but will be in places where it is needed for compatibility with the bus.

| Pins | IO Specification |

|---|---|

| D3-D15 [1] | PCA9555 |

| A1 | CPU 3.3V |

| A10, A11, A12-A31, B6, B8, B11-B20, B25-B28, B30, D1-D2 | FPGA 3.3-V LVTTL |

| A2-A9, B4, B21-B23, C11-C18 | FPGA 3.3-V LVTTL+QS3861 |

| B2 | Open drain with pull to 5V |

- ↑ These are only present on the models with the optional I2C port expander

| Pin | Description | Pin | Description | Pin | Description | Pin | Description | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| B32 | GND | A32 | GND | ||||||||

| B31 | GND | A31 | ISA_ADD_00/Chip 50004064.fpga_gpio IO 0 | ||||||||

| B30 | ISA_14_3_MHZ [1] | A30 | ISA_ADD_01/Chip 50004064.fpga_gpio IO 1 | ||||||||

| B29 | +5V [2] | A29 | ISA_ADD_02/Chip 50004064.fpga_gpio IO 2 | ||||||||

| B28 | Chip 50004040.fpga_gpio IO 1/TS mode DAT15 | A28 | ISA_ADD_03/Chip 50004064.fpga_gpio IO 3 | C19 | GND | D19 | GND | ||||

| B27 | Chip 50004040.fpga_gpio IO 2/TS mode DAT14 | A27 | ISA_ADD_04/Chip 50004064.fpga_gpio IO 4 | C18 | ISA_DAT_15/Chip 5000405c.fpga_gpio IO 15 | D18 | GND | ||||

| B26 | Chip 50004040.fpga_gpio IO 10/TS mode DAT13 | A26 | ISA_ADD_05/Chip 50004064.fpga_gpio IO 5 | C17 | ISA_DAT_14/Chip 5000405c.fpga_gpio IO 14 | D17 | Unused | ||||

| B25 | FPGA IRQ 13/TS mode DAT11 | A25 | ISA_ADD_06/Chip 50004064.fpga_gpio IO 6 | C16 | ISA_DAT_13/Chip 5000405c.fpga_gpio IO 13 | D16 | +5V [2] | ||||

| B24 | GND | A24 | ISA_ADD_07/Chip 50004064.fpga_gpio IO 7 | C15 | ISA_DAT_12/Chip 5000405c.fpga_gpio IO 12 | D15 | Chip 50004054.fpga_gpio IO 12 | ||||

| B23 | FPGA IRQ 14 | A23 | ISA_ADD_08/Chip 50004064.fpga_gpio IO 8 | C14 | ISA_DAT_11/Chip 5000405c.fpga_gpio IO 11 | D14 | Chip 50004054.fpga_gpio IO 11 | ||||

| B22 | FPGA IRQ 15 | A22 | ISA_ADD_09/Chip 50004064.fpga_gpio IO 9 | C13 | ISA_DAT_10/Chip 5000405c.fpga_gpio IO 10 | D13 | Chip 50004054.fpga_gpio IO 10 | ||||

| B21 | FPGA IRQ 16 | A21 | ISA_ADD_10/Chip 50004064.fpga_gpio IO 10 | C12 | ISA_DAT_09/Chip 5000405c.fpga_gpio IO 9 | D12 | Chip 50004054.fpga_gpio IO 9 | ||||

| B20 | TS mode DAT12 | A20 | ISA_ADD_11/Chip 50004064.fpga_gpio IO 11 | C11 | ISA_DAT_08/Chip 5000405c.fpga_gpio IO 8 | D11 | Chip 50004054.fpga_gpio IO 8 | ||||

| B19 | Chip 50004040.fpga_gpio IO 6 | A19 | ISA_ADD_12/Chip 50004064.fpga_gpio IO 12 | C10 | Unused | D10 | Chip 50004054.fpga_gpio IO 7 | ||||

| B18 | Chip 50004040.fpga_gpio IO 7/TS mode DAT10 | A18 | ISA_ADD_13/Chip 50004064.fpga_gpio IO 13 | C09 | Unused | D09 | Chip 50004054.fpga_gpio IO 6 | ||||

| B17 | Chip 50004040.fpga_gpio IO 8/TS mode DAT9 | A17 | ISA_ADD_14/Chip 50004064.fpga_gpio IO 14 | C08 | Unused | D08 | Chip 50004054.fpga_gpio IO 5 | ||||

| B16 | Chip 50004040.fpga_gpio IO 12 | A16 | ISA_ADD_15/Chip 50004064.fpga_gpio IO 15 | C07 | Unused | D07 | Chip 50004054.fpga_gpio IO 4 | ||||

| B15 | Chip 50004040.fpga_gpio IO 13 | A15 | ISA_ADD_16/Chip 5000406c.fpga_gpio IO 0 | C06 | Unused | D06 | Chip 50004054.fpga_gpio IO 3 | ||||

| B14 | ISA_IOR/Chip 5000406c.fpga_gpio IO 4 | A14 | ISA_ADD_17/Chip 5000406c.fpga_gpio IO 1 | C05 | Unused | D05 | Chip 50004054.fpga_gpio IO 2 | ||||

| B13 | ISA_IOW/Chip 5000406c.fpga_gpio IO 5 | A13 | ISA_ADD_18/Chip 5000406c.fpga_gpio IO 2 | C04 | Unused | D04 | Chip 50004054.fpga_gpio IO 1 | ||||

| B12 | ISA_MEMR/Chip 5000406c.fpga_gpio IO 6 | A12 | ISA_ADD_19/Chip 5000406c.fpga_gpio IO 3 | C03 | Unused | D03 | Chip 50004054.fpga_gpio IO 0 | ||||

| B11 | ISA_MEMW/Chip 5000406c.fpga_gpio IO 7 | A11 | ISA_AEN/Chip 50004040.fpga_gpio IO 0 | C02 | Unused | D02 | Chip 5000406c.fpga_gpio IO 9 | ||||

| B10 | GND | A10 | Chip 50004040.fpga_gpio IO 5 | C01 | Unused | D01 | Chip 5000406c.fpga_gpio IO 8 | ||||

| B09 | 8V_48V [3] | A09 | ISA_DAT_00/Chip 5000405c.fpga_gpio IO 0 | C00 | GND | D00 | GND | ||||

| B08 | Chip 50004040.fpga_gpio IO 3 | A08 | ISA_DAT_01/Chip 5000405c.fpga_gpio IO 1 | ||||||||

| B07 | Unused | A07 | ISA_DAT_03/Chip 5000405c.fpga_gpio IO 3 | ||||||||

| B06 | Chip 50004040.fpga_gpio IO 9 | A06 | ISA_DAT_04/Chip 5000405c.fpga_gpio IO 4 | ||||||||

| B05 | N/A | A05 | ISA_DAT_05/Chip 5000405c.fpga_gpio IO 5 | ||||||||

| B04 | FPGA IRQ 17/TS mode DAT8 | A04 | ISA_DAT_02/Chip 5000405c.fpga_gpio IO 2 | ||||||||

| B03 | +5V [2] | A03 | ISA_DAT_06/Chip 5000405c.fpga_gpio IO 6 | ||||||||

| B02 | Chip 20a4000.gpio IO 7 [4] | A02 | ISA_DAT_07/Chip 5000405c.fpga_gpio IO 7 | ||||||||

| B01 | GND | A01 | Chip 20a4000.gpio IO 8 | ||||||||

- ↑ Outputs a continuous 14.318180 MHz clock

- ↑ 2.0 2.1 2.2 Powering the system from PC104 5V prevents the Board's low power sleep mode from functioning.

- ↑ This pin can be used to supply power to the board through the switching regulator.

- ↑ This is automatically pulsed on startup by the ts-pc104 driver as ISA_RESET

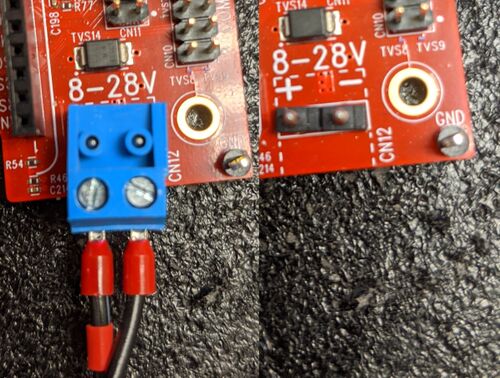

Power Connectors

| Note: | While the photos below, and shipped PCBs, may show a silkscreen of "8-28V" on the high-voltage input block, all PCB revisions from Rev. A forward support 8-48 VDC input as noted below. |

The TS-7250-V3 provides two power inputs on 2 pin removable terminal blocks. One terminal block supports 5 VDC, and one supports 8-48 VDC. Only one power input may be connected at a time. A typical power supply for this platform should provide 10 W. Refer to the specifications section for more information on power requirements.

Under the removable terminal block the PCB is labelled with the power supply polarity.

USB Ports

The TS-7250-V3 has 2 USB type A host ports. The bottom USB host port can optionally be routed to the #XBEE Header for USB cell modems.

# Route USB to XBEE

gpioset 209c000.gpio 11=1

# Route USB to bottom of J2 (default)

gpioset 209c000.gpio 11=0

Power can also be controlled to save power or reboot peripherals in the field.

gpioset 20a4000.gpio 0=0 # Turn off USB Power

gpioset 20a4000.gpio 0=1 # Turn on USB power

XBEE Header

| Note: | The socket is designed to support various radios from multiple vendors. Even within the same product line, e.g. Airgain's Skywire cell modems, some modules may deviate slightly from the standards set out by the manufacturers. Due to this, we recommend reviewing the datasheet carefully for any potential modules intended to be used in combination with this platform. Our support team (email or support portal) is happy to help advise with any questions on device compatibility. |

The CN20 header is a 2mm pitch 2x10 header which supports XBEE form factor modules. These include Nimbelink and Digi cell modems, Zigbee, Digi mesh, and other third party radios.

For Cell radios that use USB this must be enabled. This turns off USB to the bottom port on the dual high type A connector. Only enable if this is compatible with your module:

# Turn on the USB

gpioset 209c000.gpio 11=1

This header can provide 3.3V or 4V as some cell radios require higher voltage. Only enable one power supply to match your radio:

## For 3.3V modules:

#gpioset 50004040.fpga_gpio 4=1

## For 4V modules:

#gpioset 50004040.fpga_gpio 11=1

# Reset to the modem is controlled with:

gpioset

# If your modem supports USB, this must be enabled,

# disabling the lower external USB port and enabling

# the modem's.

gpioset 209c000.gpio 11=1

# Some modems require NIM_PWR_ON to be "pressed" before they

# turn on. WARNING: If the modem is already on, this same

# sequence may turn it off.

#gpioset 209c000.gpio 31=1

#sleep 1

#gpioset 209c000.gpio 31=0

For example, this initialization is known to work for these modules:

- NL_SW_LTE_S7588-T-C

- NL_SW_LTE_SVZM20-B

gpioset 209c000.gpio 11=1 # Route USB to nimbelink

gpioset 6 11=1 # Turn on 4V

gpioset 209c000.gpio 31=1 # assert NIM_PWR_ON

sleep 1

gpioset 209c000.gpio 31=0 # deassert NIM_PWR_ON

For serial modules refer to these related links:

- Technologic Systems: A friendly introduction to XBEE

- Digi's C library for XBEE API mode

- Digi's Python XBEE library

- Digi's C# Library

- Digi's Java Library

- libxbee3 (community XBEE library)

This sample code can be used to verify connectivity to the serial based modules:

wget http://ftp.embeddedTS.com/ftp/ts-arm-sbc/ts-7840-linux/samples/xbeetest.c

gcc xbeetest.c -o xbeetest

gpioset 6 4=1 # Turn on only 3.3V

./xbeetest /dev/ttymxc3

This will print out the module information such as:

XBee3 Zigbee TH RELE: 100A Build: Apr 16 2020 19:00:33 HV: 424E Bootloader: 181 Compiler: 8030001 Stack: 6710 OK

| Signals | Pin Layout | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Specifications

IO specifications

| IO Type | Voltage max | Absolute max | Source Current | Sink Current | VIL | VIH |

|---|---|---|---|---|---|---|

| CPU 3.3V | 3.3V | 3.6V | 0.99 | 2.31 | ||

| CPU 3.3V+QS3861 | 5V | 7V | ||||

| FPGA 3.3-V LVTTL | 3.3V | 3.6V | 6mA | 6mA | ||

| FPGA 3.3-V LVTTL+QS3861 | 5V | 7V | 6mA | 6mA | ||

| PCA9555 | 5.3V | 6V | 25mA [1] | 8-24mA | 0.3V | 2.31V |

- ↑ "Each I/O must be externally limited to a maximum of 25 mA and each octal (IO0_0 to IO0_7 and IO1_0 to IO1_7) must be limited to a maximum current of 100 mA for a device total of 200 mA. The total current sourced by all I/Os must be limited to 160 mA

Power Consumption

The TS-7250-V3's i.MX6UL CPU is very flexible with power. It can change the running frequency as needed to consume less power or to allow for more processing power.

The Ethernet can be put into a lower power state by bringing them up, and back down on startup. This is not done by default, and helps power savings regardless of if Ethernet is connected.

ifconfig eth0 up

ifconfig eth1 up

ifconfig eth0 down

ifconfig eth1 down

ifconfig wlan0 up # only needed if WIFI is present

These tests were run with 5V input. Unless otherwise specified these tests are run with no external connections except power, booted over eMMC at an idle prompt. The above ifconfig commands are included in our tests.

| Test | Avg. (W) | Peak (W) |

|---|---|---|

| Idle | 0.77 | 1.29 |

| CPU fully loaded [1] | 1.03 | 1.45 |

| CPU idle, single Ethernet port up and active [2] | 1.17 | 1.75 |

| CPU fully loaded [1], single Ethernet port up and active [2] | 1.40 | 2.03 |

| Supervisory Microcontroller sleep mode (ARM CPU off) | 0.055 | 0.063 |

Power Input Specifications

The TS-7250-V3 supports 2 input ranges. The 5 VDC input on CN2, and the 8-48 VDC input on CN12. The 8-48 VDC input can also come from the PC/104 connector's +12V signal.

| Input | Min range | Max Range |

|---|---|---|

| 5 VDC | 4.7 VDC [1] | 5.2 VDC |

| 8-48 VDC [2] | 8 VDC | 48 VDC |

- ↑ This requires requires at least 4.7 V to start up, and the onboard supervisory microcontroller will trigger a brownout reset if this dips below 4 V. While the TS-7250-V3 will continue to operate at this low of a voltage, any connected devices using the 5 V rail directly such as USB may not function as intended this low.

- ↑ Note the the CN2 Power Connector may have

8-28Von the PCB silkscreen; every PCB revision from Rev. A and forward support the full 8-48 VDC range. Please contact us if you have any concerns on this.

Revisions and Changes

FPGA Changelog

See the current FPGA revision from the u-boot output:

Model: Technologic Systems i.MX6UL TS-7250-V3 Board: TS-7250-V3 REV A FPGA: Rev 24 (47555b21) DRAM: 1 GiB

Or from Linux:

root@tsimx6:~# tshwctl -i MODEL=7250 FPGA_REV=24 FPGA_HASH="47555b21" OPTS=0x0 RAM_MB=1024 PCBREV=A

| Revision | Changes |

|---|---|

| 24 | Initial release |

| 45 |

|

| 49 |

|

| 50 |

|

| 51 |

|

| 52 |

|

| 53 |

|

| 56 |

|

See #Onboard_Firmware_Updates for more details on updating the system.

Note that since the release of REV C PCBs, REV A hardware should not use past REV 52. The update script shown above will update a REV C and later to the newest revision, and REV A to rev 52.

After updating the board must get a full power cycle to load the new bitstream. If the FPGA update fails then this must come back on an RMA to be recovered.

Microcontroller Changelog

On the engineering sampling units (REV A PCB) the microcontroller is a Silicon labs part, but this has been replaced with a Renesas RA4M2 on REV C and later. The REV C and later boards can be updated in the field:

| Revision | Description |

|---|---|

| 23 |

|

| 35 |

|

| 41 |

|

| 42 |

|

| 43 |

|

| 44 |

|

| 47 |

|

See the tssupervisorupdate project for instructions on updating to the latest release.

PCB Revisions

| Revision | Description |

|---|---|

| A |

|

| C |

|

U-Boot Changelog

Unless you are experiencing issues it is not recommended to change u-boot. If the board is written with an invalid u-boot this will require an RMA to recover.

| U-boot Links | Changes |

|---|---|

| SPL-20210513 u-boot-dtb-20210513.img | Initial release |

| SPL-20211015 u-boot-dtb-20211015.img |

|

| SPL-20230203 u-boot-dtb-20230203.img |

|

| SPL-20240820 u-boot-dtb-20240820.img |

|

Onboard Firmware Updates

The FPGA, supervisory microcontroller, and u-boot can all be updated in the field.

The supervisory microcontroller supports atomic updates so it is safe to update at any time, but the FPGA or u-boot must rewrite their running location. If an FPGA or u-boot update are interrupted at the wrong time this may require an RMA to recover.

Its recommended to run from the latest Debian headless image to run the updates, but the updates should run anywhere that has tssupervisorupdate. To run our update script:

wget https://files.embeddedts.com/ts-arm-sbc/ts-7250-v3-linux/update/update

chmod a+x ./update

./update

reboot

The updates will take effect on the next boot.

Product Notes

FCC Advisory

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used properly (that is, in strict accordance with the manufacturer's instructions), may cause interference to radio and television reception. It has been type tested and found to comply with the limits for a Class A digital device in accordance with the specifications in Part 15 of FCC Rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference, in which case the owner will be required to correct the interference at his own expense.

If this equipment does cause interference, which can be determined by turning the unit on and off, the user is encouraged to try the following measures to correct the interference:

Reorient the receiving antenna. Relocate the unit with respect to the receiver. Plug the unit into a different outlet so that the unit and receiver are on different branch circuits. Ensure that mounting screws and connector attachment screws are tightly secured. Ensure that good quality, shielded, and grounded cables are used for all data communications. If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The following booklets prepared by the Federal Communications Commission (FCC) may also prove helpful:

How to Identify and Resolve Radio-TV Interference Problems (Stock No. 004-000-000345-4) Interface Handbook (Stock No. 004-000-004505-7) These booklets may be purchased from the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

Limited Warranty

See our Terms and Conditions for more details.

| WARNING: | Setting any of the eMMC's write-once registers (e.g. enabling enhanced area and/or write reliability) will immediately void ALL of our return policies and replacement warranties. This includes but is not limited to: the 45-day full money back evaluation period; any returns outside of the 45-day evaluation period; warranty returns within the 1 year warranty period that would require SBC replacement. Our 1 year limited warranty still applies, however it is at our discretion to decide if the SBC can be repaired, no warranty replacements will be provided if the OTP registers have been written. |

Trademarks

Arm and Cortex are registered trademarks of Arm Limited (or its subsidiaries) in the US and/or elsewhere.